Ready mix concrete

Ready Mix Concrete

Ready-mix concrete (RMC) is a specialized material used extensively in construction, consisting of a blend of cement, water and aggregates (like sand, gravel, or crushed stone). The key feature of ready-mix concrete is that it is produced in a batch plant according to the desired specifications, then delivered to the construction site in a freshly mixed, unhardened state.

GRADE

GRADE

GRADE

GRADE

GRADE

GRADE

GRADE

GRADE

HIGH QUALITY

TIME EFFICIENCY

CUSTOMIZATION

VERSATILITY

CONSISTENT QUALITY

TIME SAVING

ENHANCED WORKABILITY

COST EFFICIENCY

REDUCED MAINTENANCE

DURABILITY

FAQ

- What is Ready Mix Concrete (RMC)?

- Ready Mix Concrete is a type of concrete that is manufactured in a batching plant according to a set recipe, then delivered to a construction site in a ready-to-use condition.

- Why choose Ready Mix Concrete over traditional on-site mixing?

- Ready Mix Concrete offers consistent quality, saves time and labor on-site, reduces wastage, and ensures precise mix proportions, resulting in stronger, more durable structures.

- Can Ready Mix Concrete be customized for specific project requirements?

- Yes, Ready Mix Concrete can be tailored to meet specific project needs by adjusting mix proportions, additives, or admixtures to achieve desired strength, durability, and workability.

M7.5

Suitable for non-structural applications such as leveling and bedding for footings, pathways, and simple residential projects.

M10

It is typically used for non-structural work like pathways, minor residential foundations, and other light-duty applications.

M15

It is suitable for light-duty pavements, pathways, and other similar applications where moderate strength is required.

M20

It is commonly used in residential construction for foundations, footings, and lightly reinforced structures.

M25

It is suitable for medium-duty applications such as beams, columns, and slabs in residential and commercial buildings.

M30

It is often used in heavy-duty structural applications such as bridges, retaining walls, and high-rise buildings.

M35

It is suitable for high-strength structural components and heavy-duty construction projects requiring superior durability and load-bearing capacity.

M40

These grades are used in specialized applications such as precast concrete elements, high-rise structures, and infrastructure projects where extreme strength and durability are essential.

LATEST BLOGSVIEW MORE

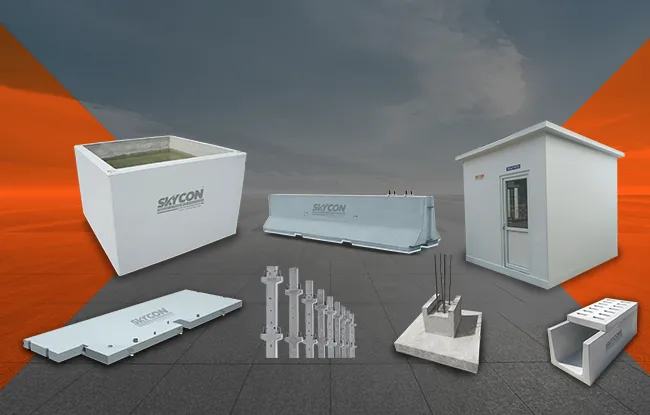

Precast Products In Modern Construction

The Ultimate Guide to Paver Blocks